Specification Guide

Learn how to procure CARES certified steel products

To specify CARES certification that meets government and private sector quality assurance and responsible sourcing requirements use the text below in your project specifications. Any references to standards refer to the current versions. To confirm any edits/changes or for more information, please contact us.

Steel Reinforcement

All reinforcement shall conform to BS 4449, BS 4482 or BS 4483 as appropriate. All stainless-steel reinforcement shall conform to BS 6744. All reinforcement shall be cut and bent in accordance with BS 8666. The reinforcement shall be obtained from firms holding valid CARES product conformity scheme certificate of approval for the production and supply of the steel reinforcement.

When specifying steel reinforcement do not refer to EN 10080 without referencing BS 4449 and the grade, B500A, B500B or B500C, because EN 10080 is an ‘open Standard’ and does not contain any product performance requirements.

Any references to standards refer to the current versions.

The reference to “(or fully equivalent scheme)” is only required for projects subject to public procurement regulations in the UK.

Reinforcement traceability system

All reinforcement delivered to site shall be fully traceable to the cast/heat/batch number, reinforcement supplier and reinforcement manufacturer. The reinforcement product test data and a valid CARES certificate of approval shall be provided for the reinforcement supplier(s) and reinforcement manufacturer(s). Each bundle of reinforcement - straight bar, cut/bent, fabric, reinforcement mat, or pre-assembled welded fabrication - shall be identifiable with a suitable and durable tag or label securely attached to the product.

Digital construction

All reinforcement manufacturers and suppliers shall use the ‘CARES Cloud’ digital traceability platform.

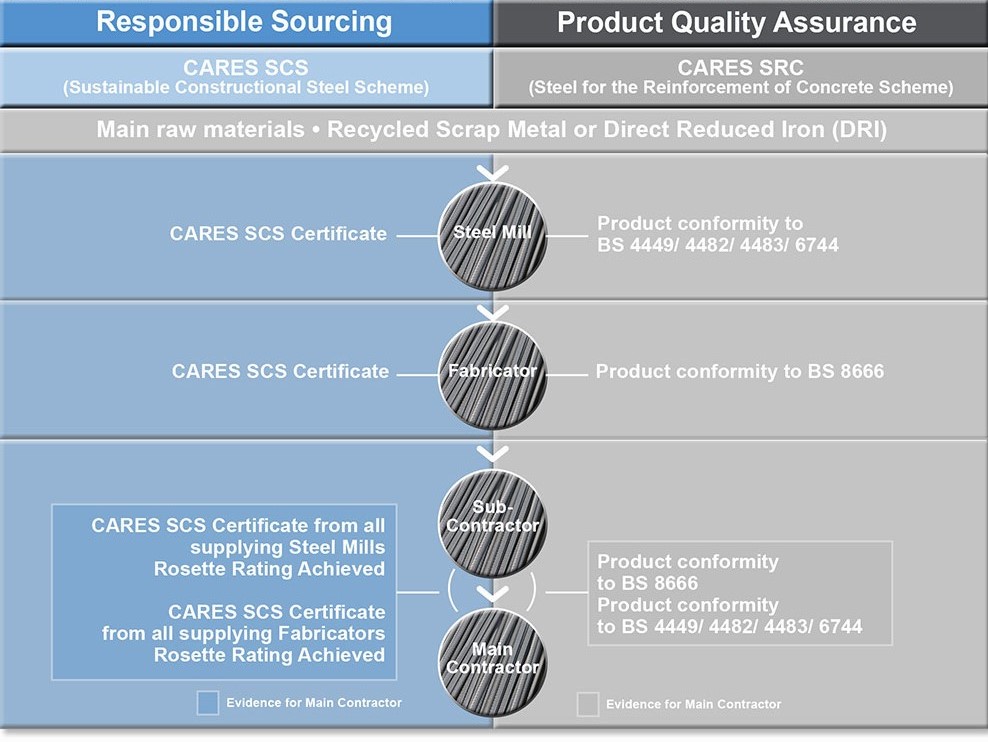

Sustainable construction and responsible sourcing

All reinforcement suppliers shall hold a valid CARES Sustainable Constructional Steel (SCS) Scheme Certificate of Approval for the manufacture and/or fabrication issued by CARES. They shall provide the Rosette Ratings achieved by the manufacturer and the fabricator, where achieved.

The reinforcement manufacturer shall additionally provide an independently verified Environmental Product Declaration (EPD) which conforms to EN 15804.

Storage

All reinforcement shall be delivered in properly identified tagged bundles, reinforcement mats or pre-assembled welded fabrications and shall be stored on site in a manner so as not to become contaminated by deleterious materials or otherwise damaged. Fabric shall be stored flat.

Handling

Reinforcement shall not be dropped from height, mechanically damaged or shock loaded in any way.

Pre-assembled welded fabrications delivered to site

Welding shall be carried out in accordance with BS EN ISO 17660, BS 8548 and CARES Steel for the Reinforcement of Concrete (SRC) scheme Appendix 11 and/or 12, as appropriate (or fully equivalent scheme).

All suppliers welding reinforcement shall hold a valid CARES Steel for the Reinforcement of Concrete (SRC) scheme Certificate of Approval to CARES SRC Appendix 11 and/or 12, as appropriate (or fully equivalent scheme).

Continuity strips

The continuity strip manufacturers shall hold a valid CARES Technical Approval scheme Certificate of Approval to TA2 Quality and Operations Schedule for the Technical Approval of Reinforcement Continuity Systems or fully equivalent scheme.

All continuity strip manufacturers shall hold a valid CARES Technical Approval scheme Certificate of Approval (or fully equivalent scheme).

All continuity strip suppliers shall hold a valid CARES ISO 9001 Certificate of Approval.

Mechanical Couplers

All mechanical coupler manufacturers shall hold a valid CARES Technical Approval scheme Certificate of Approval to CARES Technical Approval (or fully equivalent scheme).

All mechanical coupler suppliers shall hold a valid CARES SRC Appendix 8 scheme Certificate of Approval (or fully equivalent scheme). When specifying mechanical coupler systems, it should be noted there are different types of CARES Technical Approval:

All continuity strip suppliers shall hold a valid CARES ISO 9001 Certificate of Approval.

• TA1-A - Quality and Operations Schedule for the Technical Approval of Couplers for Reinforcing Steel

for use in Structures and Structural elements Designed in accordance with the Fatigue Requirements

of Structural Eurocodes

• TA1-B - Quality and Operations Schedule for the Technical Approval of Couplers for Reinforcing Steel

and Reinforcement Anchors For BS8110 and EN1992-1-1 Applications for Static Loading in Tension or

Tension and Compression

• TA1-C - Quality and Operations Schedule for the Technical Approval of Tension Couplers for

Reinforcing Steel for Sellafield Standard Applications

• TA1-F - Quality and Operations Schedule for the Technical Approval of Reinforcement Continuity

Systems. The suppliers of the mechanical couplers shall hold a valid CARES SRC scheme certificate

of approval to Appendix 8 - Mechanical coupling of reinforcing steel.

Punching shear reinforcement systems

All punching shear reinforcement system manufacturers shall hold a valid CARES Technical Approval scheme Certificate of Approval (or fully equivalent scheme). Only required for projects subject to public procurement regulations in the UK).

All punching shear reinforcement system reinforcement suppliers shall hold a valid CARES ISO 9001 Certificate of Approval.

The punching shear reinforcement system manufacturers shall hold a valid CARES Technical Approval scheme Certificate of Approval to TA7 Quality and Operations Schedule for the Technical Approval of Stud Shear Reinforcing Systems for Flat Slabs.

High tensile steel wires and strands

High tensile steel wires and strands shall comply with BS 5896 and shall be obtained from an organisation holding a valid CARES Supply and Installation of Post Tensioning Systems for Concrete Structures Scheme certificate of approval for the production of prestressing steel wires and strands to CARES Appendix PT8 (or fully equivalent scheme).

Cold Worked High Tensile Alloy Bar

Cold worked high tensile alloy steel bars for prestressed concrete shall comply with BS 4486 and shall be obtained from an organisation holding a valid CARES Supply and Installation of Post Tensioning Systems for Concrete Structures Scheme certificate of approval for the production of prestressing steel bars to CARES Appendix PT7 (or fully equivalent scheme).

Only firms that have achieved full certification under the CARES Supply and Installation of Post Tensioning Systems for Concrete Structures Scheme shall be permitted to bid for or undertake contracts to supply and install post-tensioning systems.

CARES Approved Post Tensioning System suppliers and installers shall only use Post Tensioned kits holding valid European or UK Technical Approvals, or Post Tensioned kits approved to CARES Supply and Installation of Post Tensioning Systems for Concrete Structures Scheme Appendix PT3.

CARES Approved Post Tensioning System suppliers and installers shall only use pre-bagged grout material to CARES Supply and Installation of Post Tensioning Systems for Concrete Structures Scheme Appendix PT10.

CARES Model Specification for Bonded and Unbonded Post-tensioned Concrete Floors (UK)

There are several documents that deal with various aspects of post-tensioning of flat slabs, however none comprehensively deals with the technical aspects of post-tensioning in building construction. Consequently, CARES has produced a model specification as a guide to specification writers. This is freely available in PDF format from: Model specification for bonded and unbonded Post-tensioned Concrete Floors.

Technological advances and digital tools have brought fundamental improvements in the way we design and deliver projects. Yet the prevalence of these tools has also opened opportunities for those with different motives. The ready reliance on digital data means information can be shared seamlessly and relied on instinctively. When fake data is entered into this system the consequences can be devastating. There have been many high-profile instances of data being manipulated in this way to secure commercial advantage; distorting test results or building false confidence in a product’s performance characteristics. The result is that trust is shattered; confidence in the accuracy of information evaporates – and the technology which offered so much potential is regarded with suspicion. CARES has now stepped into this space to restore trust in one of the most important elements in a project’s development: constructional steels sitting at the heart of every significant development.

Once used, and sited within the development’s concrete reinforcement, this steel cannot be removed even if there is a product failure or a manufacturing deficiency. There is no ‘product recall’ when things go wrong with steel in the structure of a prized project. Its performance must be assured from the outset. Without confidence, built on trust in the steel embedded in the structure, the project is fundamentally flawed. CARES delivers that trust through its cherished independence, proven track record, industry knowledge and auditing approach.

A critical factor in clients’ requesting CARES services is the growing appreciation of the aggregated knowledge shared among CARES team of expert international auditors. Hands-on inspection at the point of manufacture and processing is the recognised ‘gold standard’ in product assurance, in turn lifting client confidence to the point where there is instinctive trust in CARES certification results.

Understanding a product’s provenance in this way brings additional benefits to those specifying critical materials entering the construction supply chain. Designers, engineers, consultants, specifiers and main contractors can seamlessly rely on the information they receive from CARES when the product’s provenance is captured in a simple, secure, tool. This is the step change now underway.

Following a significant investment in research and development CARES has launched its own digital route to reinforcing steel certainty: the CARES Cloud. It represents a game changing moment.

This product draws together not only confidence in CARES’ assurance processes, but invaluable simplicity in a world of increasingly complex supply chains.

Making sure products are effectively tested, marketed and traceable complements CARES’ independent assurance of product compliance from the CARES-assured supply chain. This supply chain includes the manufacturers and processors of reinforcing steels and enables real-time analysis of the product entering the supply chain, including a level of detail which transforms the understanding of that product’s characteristics.

With the CARES Cloud an accurate Global Warming Potential (GWP) value for each tonne of reinforcing steel delivered to a particular project is instantly available; information relating to the manufacturing facilities; the product’s composition and even details relating to the manufacturer’s employment practices, will in future, be overlaid to create a full picture of the product’s sustainability characteristics. This is particularly important in public sector procurement and to support industry meeting ‘Net Zero’ commitments, where the ongoing search for accurate sustainability performance measurement will be enhanced through access to the CARES Cloud.

As the level of detail demanded by procurement bodies increases, then the scope for enhanced data – bringing further transparency – creates a virtuous circle, futureproofing information across the project’s lifetime. This offers invaluable understanding for safety critical materials such as rebar, where performance knowledge will surely change and develop over time.